De levendige veelzijdigheid van gemetalliseerde PVC/PET-folie in moderne toepassingen

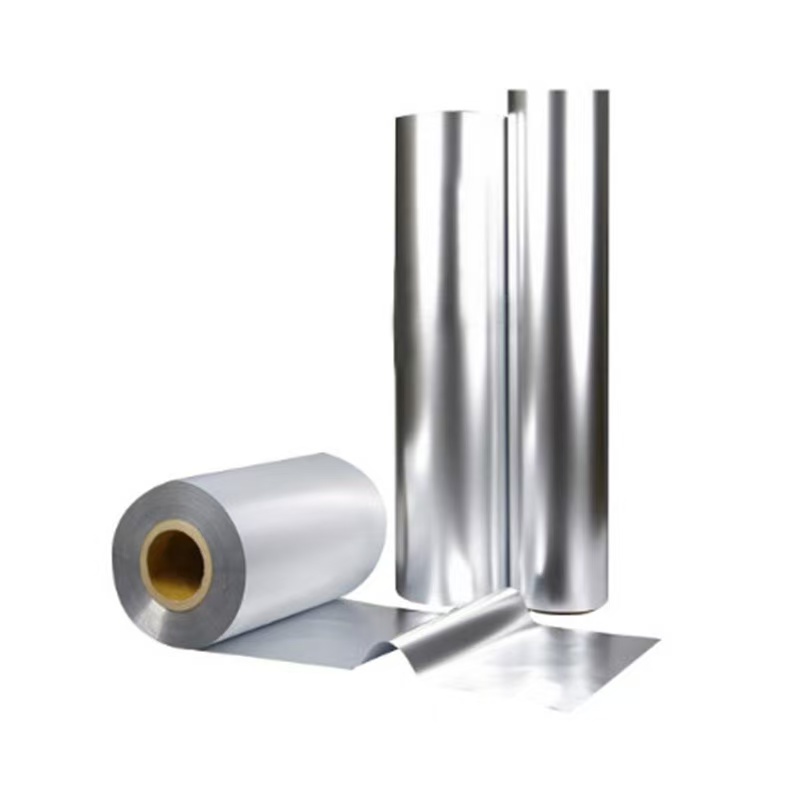

2025-06-30 15:37PVC (Polyvinyl Chloride) and PET (Polyethylene Terephthalate) metallized films, often referred to as PVC/PET metallized films, are advanced materials that combine the inherent properties of their base polymers with the aesthetic and functional benefits of a metallic coating. These films, characterized by their vibrant, reflective surfaces and exceptional versatility, are widely used in industries ranging from packaging to construction. The metallization process, typically involving the deposition of a thin aluminum layer, enhances their visual appeal, barrier properties, and durability. This article explores the unique characteristics of PVC/PET metallized film and its diverse applications, such as blister packaging, quick-freeze boxes, decoration, antistatic solutions, and flame-retardant films, supported by scientific insights and practical examples.

Characteristics of PVC/PET Metallized Film

PVC/PET metallized films are engineered to offer a unique blend of aesthetic, mechanical, and chemical properties, making them suitable for a wide range of applications. Below are their key characteristics:

1. High Reflectivity and Aesthetic Appeal

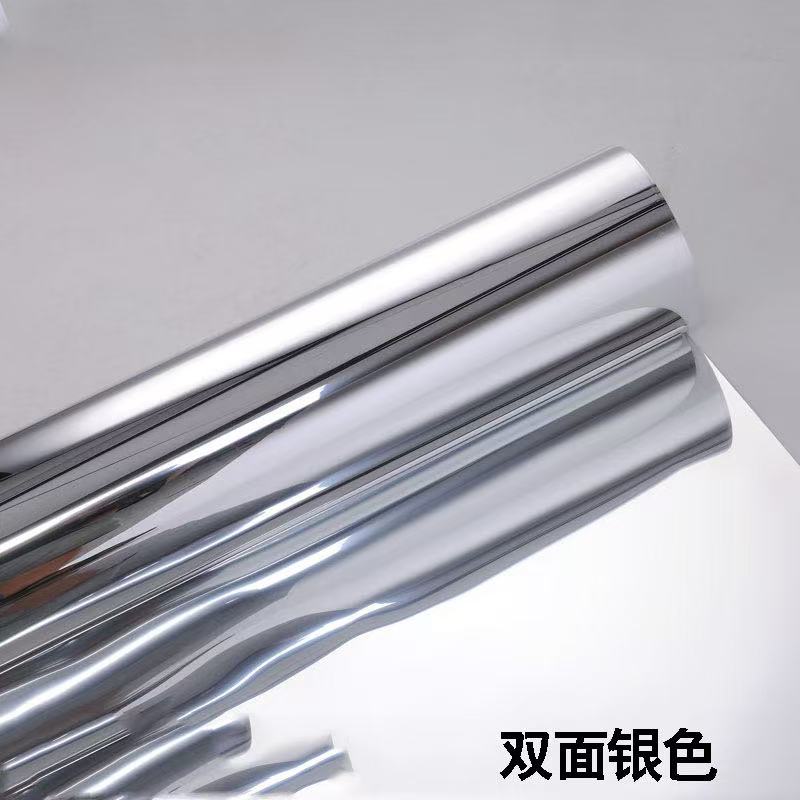

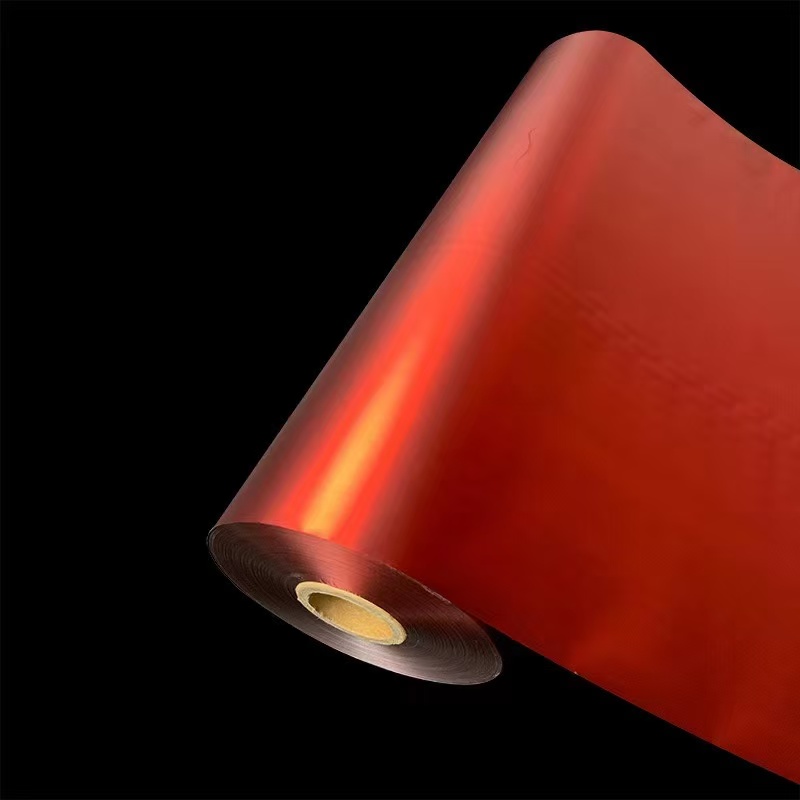

The metallized layer, typically aluminum, gives PVC/PET metallized film a mirror-like finish and vibrant, multicolored effects, depending on the coating process. This reflective quality enhances visual appeal, making it ideal for decorative and packaging applications. For instance, PET-based metallized films often achieve a light reflectivity rate of over 85%, according to optical material studies, rivaling polished metal surfaces. The glossy, colorful appearance makes these films a favorite for premium packaging and interior design.

2. Excellent Barrier Properties

The aluminum coating significantly enhances the barrier properties of PVC/PET metallized film, offering superior protection against moisture, oxygen, and UV light. PET metallized films, in particular, have a low oxygen transmission rate (OTR) of less than 1 cm³/m²/day, making them ideal for preserving perishable goods. PVC metallized films, while slightly less effective as gas barriers, still provide robust moisture resistance, suitable for humid environments.

3. Durability and Mechanical Strength

Both PVC and PET metallized films exhibit excellent mechanical strength. PET films are known for their high tensile strength (up to 200 MPa) and dimensional stability, making them resistant to tearing and deformation. PVC films, while slightly less rigid, offer flexibility and impact resistance, ideal for applications like blister packaging. The metallized layer adds an additional protective coating, enhancing durability against abrasion and wear.

4. Thermal and Chemical Stability

PET metallized films can withstand temperatures up to 150°C, making them suitable for applications involving heat sealing or sterilization. PVC metallized films, with a lower heat tolerance (around 80°C), are still effective for many packaging and decorative uses. Both materials resist a wide range of chemicals, including acids and alkalis, ensuring stability in harsh environments, such as packaging for cleaning agents or industrial chemicals.

5. Customizable Functional Properties

PVC/PET metallized films can be tailored with additives to meet specific needs, such as antistatic agents for electronics or flame-retardant compounds for safety applications. The metallization process itself can be adjusted to achieve different levels of opacity or color effects, allowing manufacturers to produce films ranging from fully reflective to semi-transparent, multicolored variants.

6. Recyclability Challenges and Opportunities

While PET is more recyclable than PVC due to established recycling streams, both materials face challenges in recycling when metallized. The aluminum layer complicates separation processes, but advancements in chemical recycling are improving the potential for reusing PVC/PET metallized films. For example, recycled PET films are increasingly used in secondary packaging, aligning with sustainability goals.

Applications of PVC/PET Metallized Film

The unique properties of PVC/PET metallized film make it a go-to material for industries requiring both functionality and visual appeal. Below, we explore its applications in detail, highlighting how its characteristics meet specific demands.

1. Blister Packaging for Disposable Tableware

PVC/PET metallized films are widely used in blister packaging for disposable tableware, such as cutlery, plates, and cups. The films’ vibrant, reflective surfaces enhance product presentation, making items stand out on retail shelves. PET metallized films, with their superior strength and clarity, are often thermoformed into rigid trays that securely hold tableware, while PVC variants offer flexibility for softer, contoured packaging.

For example, a set of disposable forks packaged in a PET metallized blister pack benefits from the film’s durability, ensuring the contents remain intact during transport. The metallic sheen adds a premium look, appealing to consumers in catering or hospitality settings. Industry data suggests that metallized films account for approximately 25% of the blister packaging market, driven by their aesthetic and protective qualities.

2. Quick-Freeze Packaging Boxes

In the food industry, PVC/PET metallized films are used for quick-freeze packaging boxes, such as those for frozen seafood, vegetables, or ready-to-eat meals. The films’ excellent barrier properties protect contents from freezer burn and moisture loss, while their thermal stability ensures they remain intact at sub-zero temperatures. PET metallized films, in particular, are favored for their ability to maintain clarity and strength in freezing conditions.

For instance, a frozen pizza packaged in a PET metallized film box showcases the product through transparent sections while the metallic coating adds a premium, eye-catching effect. The film’s oxygen barrier properties extend shelf life, with studies showing that PET metallized films can reduce spoilage rates by up to 30% compared to non-metallized alternatives.

3. Decorative Applications in Renovation

PVC/PET metallized films are increasingly popular in construction and renovation for their decorative potential. Their reflective, multicolored surfaces are used in interior design elements, such as wall panels, ceiling tiles, or furniture laminates. PVC metallized films, being more flexible, are ideal for wrapping curved surfaces, while PET films are used for rigid, high-gloss applications.

For example, a modern office may use PET metallized film as a decorative laminate on conference room tables, creating a sleek, metallic finish that resists scratches and moisture. In residential settings, PVC metallized films are applied to cabinetry or accent walls, offering a cost-effective alternative to metal or glass. The films’ durability ensures they withstand daily wear, while their vibrant aesthetics elevate interior spaces.

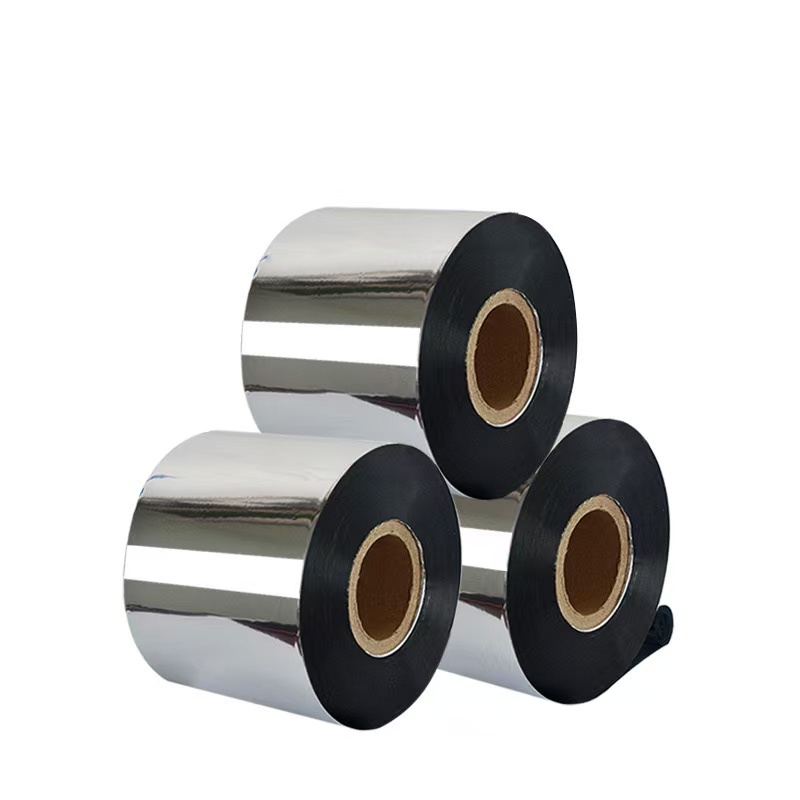

4. Antistatic PVC/PET Metallized Film for Electronics

Antistatic PVC/PET metallized films are critical in the electronics industry, where static discharge can damage sensitive components like circuit boards or microchips. The metallized layer enhances conductivity, dissipating static charges, while antistatic additives further reduce the risk of electrostatic buildup. PET films, with their superior strength, are often used for protective packaging, while PVC variants are employed for flexible wraps.

For instance, a PET metallized film bag used to package a computer hard drive ensures that the component is shielded from static and environmental damage. The film’s reflective surface also allows for clear labeling or barcoding, streamlining inventory processes. The electronics packaging market for metallized films is growing at a rate of 4% annually, driven by the demand for reliable, static-free solutions.

5. Flame-Retardant PVC/PET Metallized Film for Safety

Flame-retardant PVC/PET metallized films, infused with additives like halogenated compounds or phosphorus-based retardants, are used in applications requiring fire safety, such as construction, transportation, or public spaces. The metallized layer enhances durability, while the flame-retardant properties ensure compliance with safety regulations. These films maintain their reflective, decorative appeal, making them suitable for both functional and aesthetic purposes.

6. Consumer Goods and Retail

PVC/PET metallized films are prevalent in consumer goods, from shopping bags to gift packaging. Their vibrant, reflective surfaces make them ideal for premium retail packaging, such as cosmetics or luxury food items. PET metallized films are often used for rigid gift boxes, while PVC films are employed for flexible bags or wraps.

applications.

- PVC Environmental Concerns: PVC’s association with chlorine-based compounds raises environmental concerns, though PET is more eco-friendly.

PVC/PET metallized films are a dynamic blend of aesthetics and functionality, offering vibrant reflectivity, superior barrier properties, and customizable features. From blister packaging for tableware to flame-retardant barriers in construction, these films meet diverse industry needs with unmatched versatility. While challenges like recycling complexity and cost persist, ongoing innovations in sustainable materials and processing are paving the way for a brighter, more eco-friendly future. As industries continue to prioritize performance and visual appeal, PVC/PET metallized films will remain a shining star in materials science.