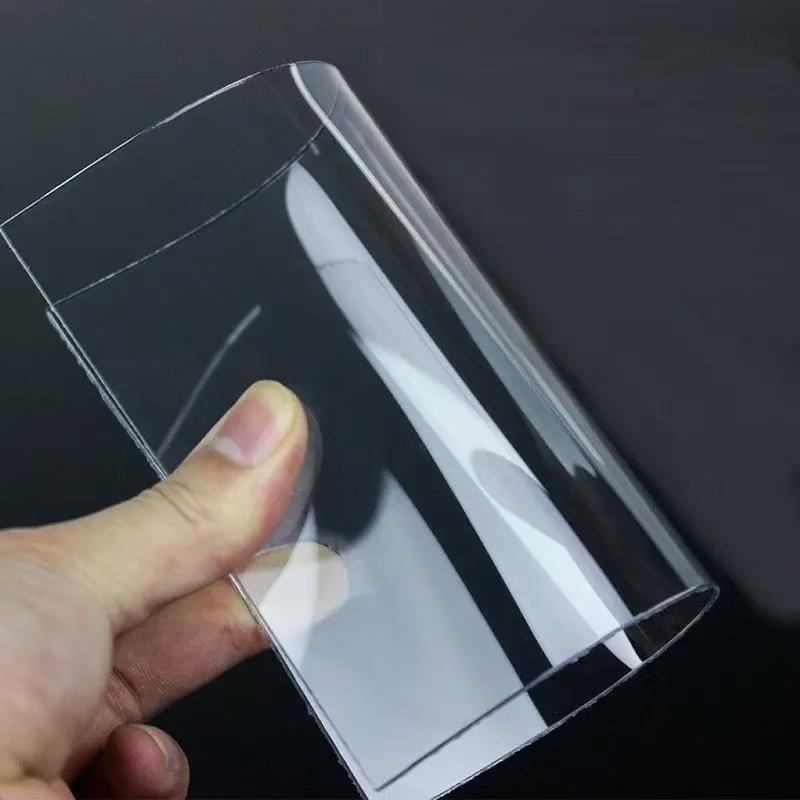

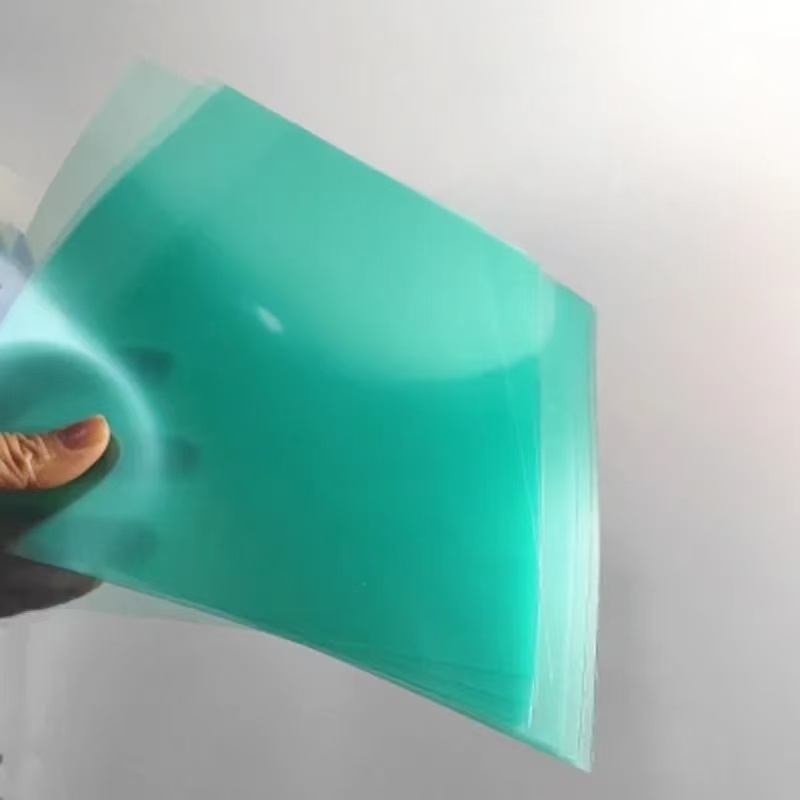

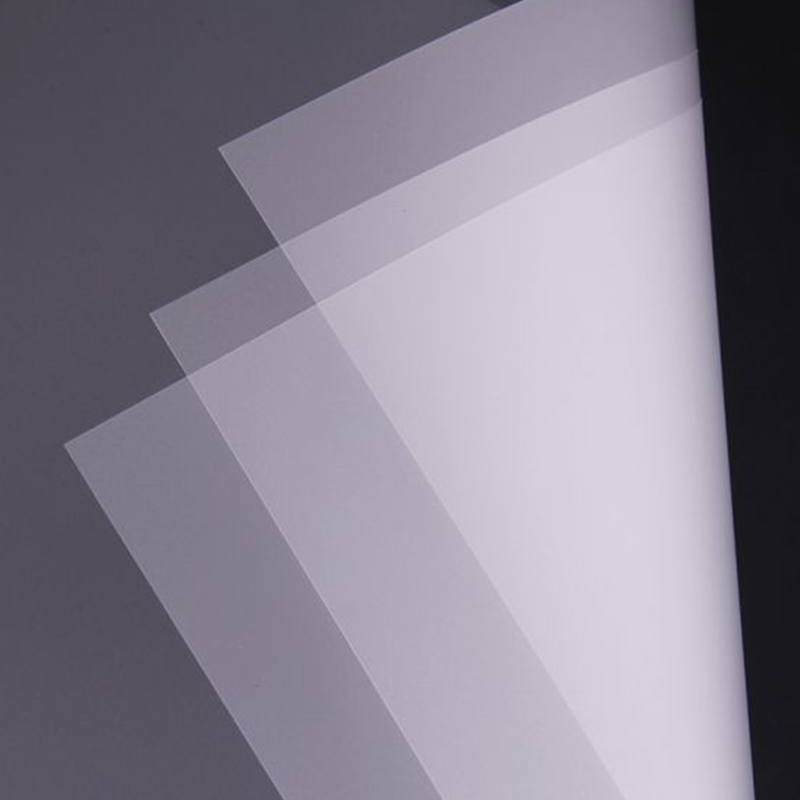

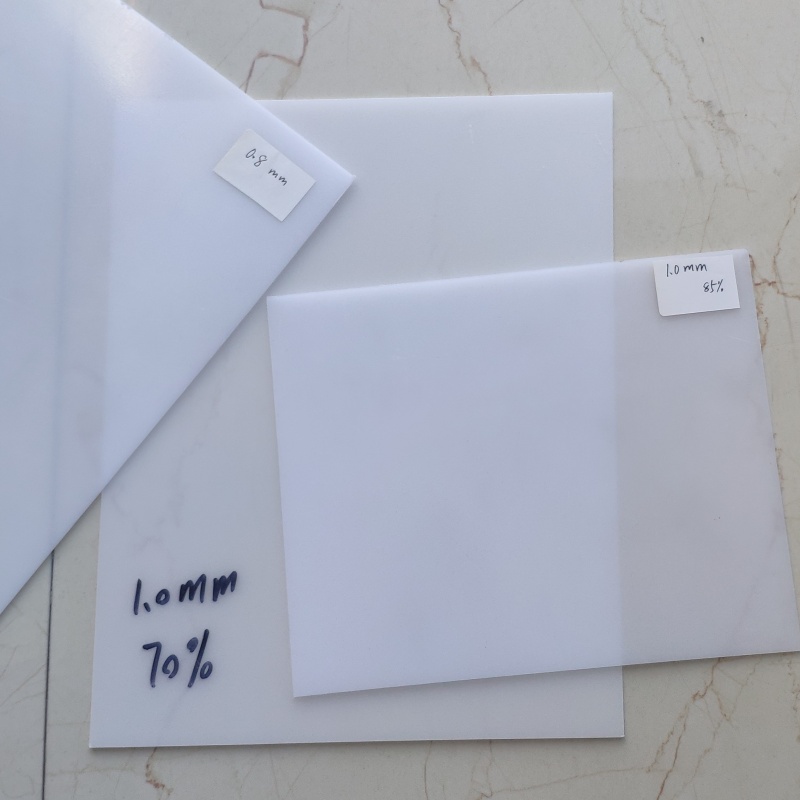

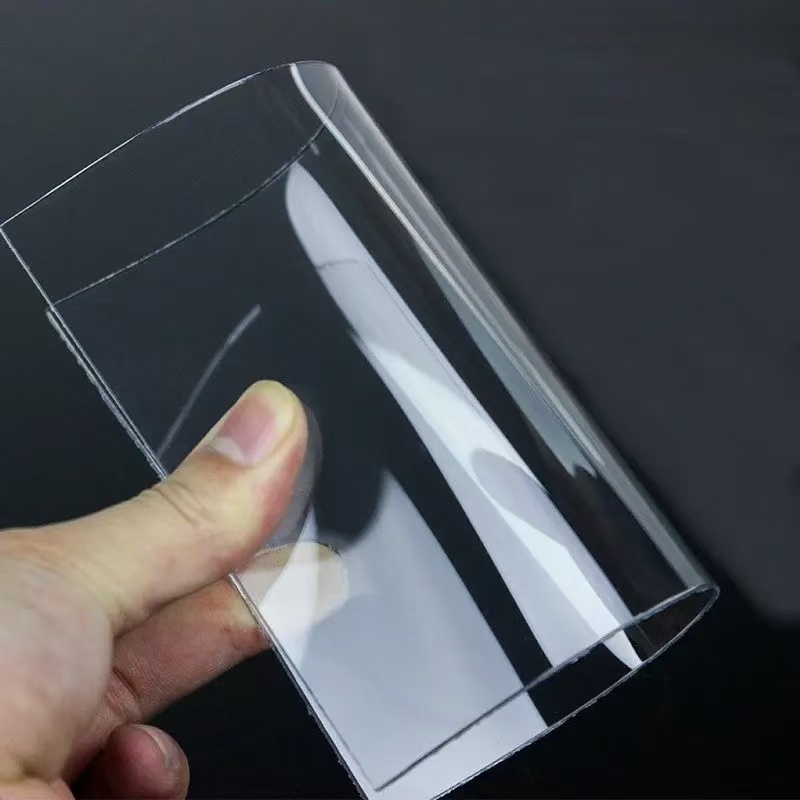

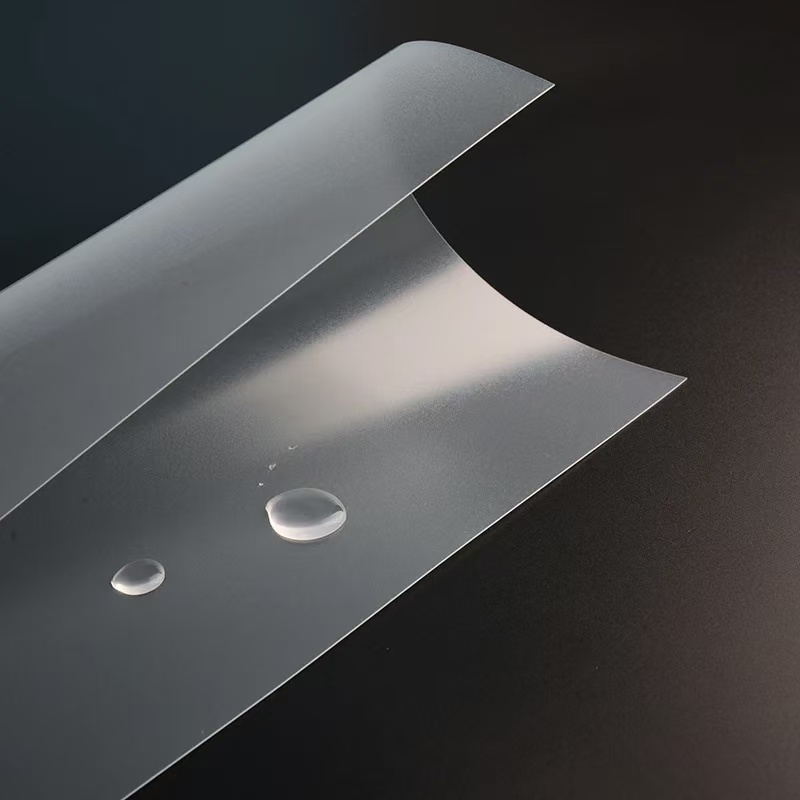

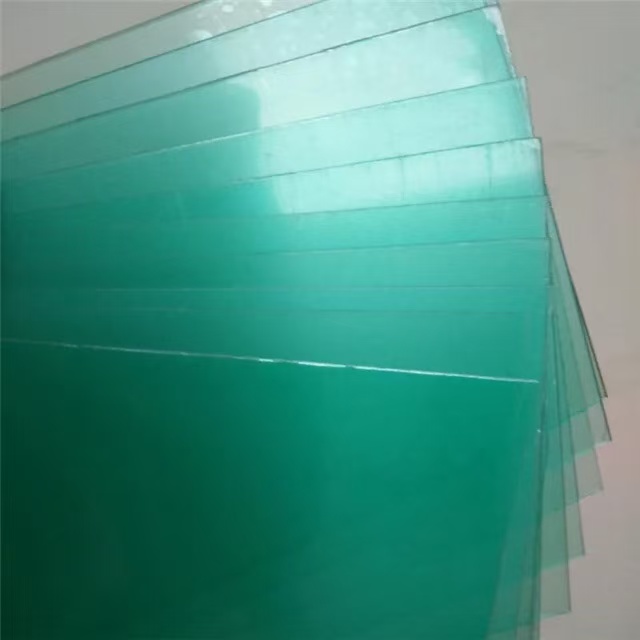

TL-PC-208 Het veelzijdige gebruik van PC-folie bij optische en beeldschermbescherming

Thickness 0.45-0.018mm-customization

Size: 80MM/1300MM/Customization

GRADE: optical

color: white/ transparent customization

location: china

- TOPLEADER

- CHINA

- 15WERKDAGEN

- 5000T/M

- informatie

- video

- Download

《The Versatile Use of PP Trays in Food Packaging》

In today's fast-paced world, packaging plays a crucial role in ensuring the safety, freshness, and convenience of food products. One type of packaging material that has gained significant popularity is the PP (polypropylene) tray. With its numerous advantages and versatile applications, PP trays have become an essential part of the food industry.

I. Food Heating Packaging

PP trays are widely used for food that can be heated. Their heat resistance makes them an ideal choice for packaging meals that need to be reheated in microwaves or ovens.

When it comes to microwave heating, PP trays are designed to withstand the high temperatures generated without melting or deforming. This allows consumers to conveniently heat up their meals without having to transfer the food to another container. The trays are also microwave-safe, which means they do not release any harmful substances into the food during heating.

For oven heating, PP trays can withstand moderate temperatures without losing their shape or integrity. This makes them suitable for packaging dishes like lasagna, casseroles, and other baked goods. The trays can be placed directly in the oven, saving time and effort in transferring the food.

Moreover, PP trays are often transparent or semi-transparent, allowing consumers to see the contents inside. This is especially useful for ready-to-eat meals or frozen dinners, as it gives consumers an idea of what they are buying and helps them make informed decisions.

The convenience of PP trays for food heating packaging is further enhanced by their stackability. Multiple trays can be stacked on top of each other, saving storage space in kitchens and pantries. This also makes them easy to transport and store in supermarkets and warehouses.

II. Meat Frozen Preservation

In the realm of meat preservation, PP trays are a game-changer. When meat is frozen, it needs to be protected from air, moisture, and contaminants to maintain its quality and freshness. PP trays provide an excellent solution for this.

The trays are designed to fit different cuts and sizes of meat, ensuring a snug fit and minimizing air pockets. This helps to prevent freezer burn and keeps the meat looking and tasting fresh for a longer period.

The material of PP trays is also impermeable to moisture, which means it prevents ice crystals from forming on the surface of the meat. Ice crystals can damage the texture and flavor of the meat, so preventing their formation is crucial for maintaining its quality.

Furthermore, PP trays can be sealed with a plastic film or lid to provide an additional layer of protection. This helps to lock in the freshness and prevent odors from escaping or other contaminants from entering.

In supermarkets and butcher shops, PP trays are often used to display and package frozen meats. The trays are easy to stack and arrange on shelves, making it convenient for customers to browse and select their desired products. The transparent nature of the trays also allows customers to see the quality and freshness of the meat, increasing their confidence in the product.

III. Fruit Preservation and Packaging

PP trays are also widely used for fruit preservation and packaging. Fruits are delicate and perishable, so they need proper packaging to maintain their freshness and quality.

For soft fruits like berries, grapes, and cherries, PP trays with individual compartments are ideal. These compartments keep the fruits separated, preventing them from being crushed or damaged. The trays also allow for proper air circulation around the fruits, which helps to prevent moisture buildup and spoilage.

For larger fruits like apples, oranges, and peaches, PP trays with a flat surface or shallow compartments can be used. These trays provide a stable base for the fruits and prevent them from rolling around during transportation and storage.

The material of PP trays is also food-safe and does not interact with the fruits, ensuring that they remain fresh and free from contaminants. Additionally, PP trays can be printed with attractive designs and labels, making the fruits more appealing to consumers.

In the fruit export industry, PP trays are often used in combination with other packaging materials like cardboard boxes and shrink wraps. The trays provide protection to the fruits during transportation, while the boxes and wraps ensure that the fruits are securely packaged and easy to handle.

IV. Other Applications

Apart from food heating packaging, meat frozen preservation, and fruit preservation and packaging, PP trays have several other applications in the food industry.

For example, they can be used for packaging dairy products like cheese, butter, and yogurt. The trays can be designed to hold different shapes and sizes of dairy products and can be sealed to prevent spoilage.

PP trays are also used for packaging snacks like nuts, chips, and candies. The trays can be customized with different colors and designs to make the snacks more attractive to consumers.

In the catering industry, PP trays are used for serving meals at events and functions. They are lightweight, durable, and easy to clean, making them a convenient option for caterers.

Moreover, PP trays can be recycled, which makes them an environmentally friendly choice. As the demand for sustainable packaging solutions grows, PP trays are likely to become even more popular in the future.

Conclusion

In conclusion, PP trays are a highly versatile and useful packaging material for the food industry. Their applications in food heating packaging, meat frozen preservation, fruit preservation and packaging, and other areas make them an essential part of modern food packaging. With their heat resistance, moisture impermeability, food safety, and recyclability, PP trays offer numerous advantages over other packaging materials. As technology continues to advance, we can expect to see even more innovative uses of PP trays in the future, further enhancing the safety, freshness, and convenience of our food products.

Binnen 15-20 dagen na ontvangst van de betaling...more